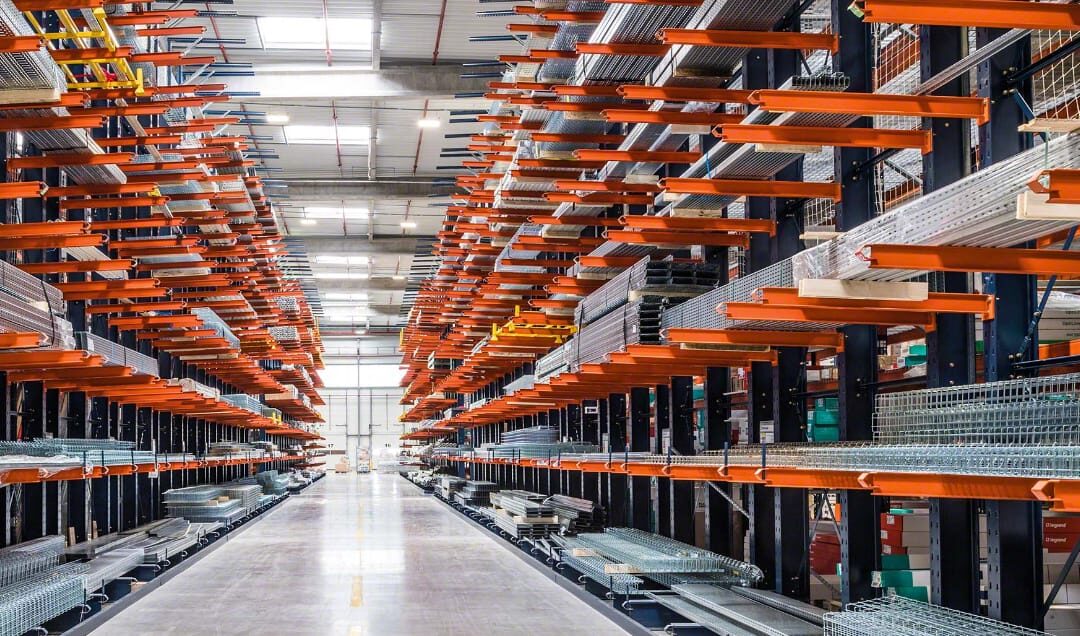

Cantilever racks are a popular storage solution for warehouses and stores that handle long, bulky items such as lumber, pipes, and sheet metal. These racks are designed to maximize storage space while providing easy access to stored materials. However, like any other warehouse equipment, proper operation and maintenance of your cantilever rack system are essential to ensure safety and longevity. Here we will discuss the top five tips for safely operating and maintaining this system.

1. Regularly Inspect it:

One of the most critical aspects of maintaining it is conducting regular inspections. These inspections should be performed by a qualified professional who can identify potential issues and recommend necessary repairs or adjustments. Look for signs of damage, such as bent arms, loose connections, or corroded components.

2. Train Your Staff on Proper Loading and Unloading Techniques

Proper training is crucial in ensuring the safe operation of these systems. Ensure that all employees responsible for loading and unloading materials are well-versed in the correct procedures. This includes understanding the weight limits and how to distribute loads evenly across the rack’s arms. Overloading or improperly loading materials can lead to accidents and damage to the racking system.

3. Keep the Area Around the Rack Clean and Organized

A well-organized and clean warehouse environment can significantly contribute to the safe operation of your rack system. Ensure that aisles are free from clutter and that there is adequate space for forklifts and other equipment to maneuver safely. Regularly clean the area around the rack to prevent the accumulation of debris, which can pose a tripping hazard and obstruct access to stored materials.

4. Incorporate High-Quality Racking Components

Investing in high-quality racking components, such as those found in dexion racking systems, can significantly enhance the safety and durability of your racks. These components are designed to withstand heavy loads and provide excellent stability, ensuring that your storage system remains sturdy and secure for years to come.

5. Develop a Preventative Maintenance Schedule

Finally, implementing a preventative maintenance schedule can help you proactively address potential issues with your racking systems before they become more significant problems. This may include periodic inspections, tightening bolts and connections, and replacing damaged or worn components. By staying on top of maintenance tasks, you can minimize downtime and reduce the risk of accidents or damage to your stored materials.

Conclusion:

By following these five tips—regular inspections, staff training, maintaining a clean workspace, using high-quality components, and implementing a preventative maintenance schedule—you can ensure the longevity and safety of your cantilever rack system.